Todd, glad to associate and actual "name" to the screen name.

Threads such as this are so useful in that it allows us to see the results of someone else's experimentation. If a process doesn't work, I can scratch that idea and move on to either come up with something better or provide the readers with yet another idea NOT to try.

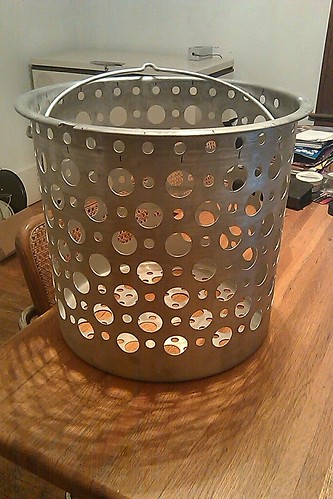

I truly was hoping that your plan of placing the bag into a basket (pierced or mesh) would work well. I was envisioning a little crane that would hoist the basket/bag up, move it over, and lower it into another smaller pot in case I wanted to dunk again (as in Maxi-BIAB).

I'm thinking that, when the voile bag is suspended, the weight causes the weave to stretch slightly, allowing the wort to drain more freely while still filtering most of the grain. When the bag is supported inside a basket, the cloth does not stretch; in fact, the "pores" in the weave might actually be compressed slightly even further restricting the flow.

Since you're appearing much more active in your pursuit than I, I'll throw out an idea that I've been pondering ever since reading the thread on this site in which the brewer purchased fine stainless steel cloth with which to make a basket that would actually replace the bag completely. Maybe you can beat me to it:idea:

I would hack up a plastic pale (or metal basket if I feel up to it) that's about the size of the basket that came with your kettle probably much like what you had envisioned doing with your basket. Perhaps cut out pie slices from the bottom to give it 4-6 "spokes", then cut rectangles from the sides to match. Now I would have mostly a framework to which I could attach the stainless steel fabric. It would resemble the adapter I use to put my own coffee grounds into my Keurig coffeemaker.

It suddenly hit me that one might even try placing the voile bag into this support as an initial experiment before trying to mess with termite cloth or other SS cloth. If my theory is correct, some of the bag would buldge thru the cutouts in the bottom and sides thereby allowing the wort to pass thru more freely than it does in a much more supportive basket such as your - or even the wire ones in the links I posted.

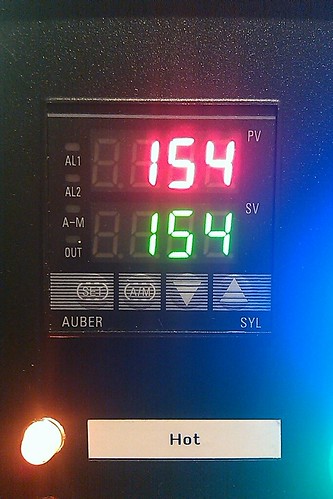

The road to Hell is paved with good intentions, so it might be best to follow the advice of the hosts of our forum and just K.I.S.S. We should leave all the fanciness to the traditional all-grain guys and their large 3-vessel flat brew sculpture with the three gleaming SS kettles, all the plumbing, shiny quick-connect fittings, and, of course, the big bright lights on the controller as shown on The Electric Brewery

You gotta admit, though, that there's something really stimulating to the eyes about some of those rigs.

Better go, now. Going to look at a house today (we're house-hunting) - of course, keeping in mind the placement of a temp-controlled garage/shop in which I can set up my pipe organ (my other money-pit hobby) as well as my brew station.

Thanks,

Keith