I’m an Italian homebrewer and I have started some moths ago a project in order to build a single vessel electric heated brewing system ..something similar to the well known Speidel Braumeister . The main driver behind this project was to build an “all in one” system very compact, light, easy to use, easy to clean system that implements the BIAB process and brewing philosophy

Now I’m completing last construction details and I’m near to close the “make” phase and start testing the system. In order to understand all the fundamentals of BIAB brewing I have registered the forum and started reading the posts. Lot of useful information and ideas … and viceversa I would like to share my project details open to any comments and suggestions

Let’s start from some construction details and schema !

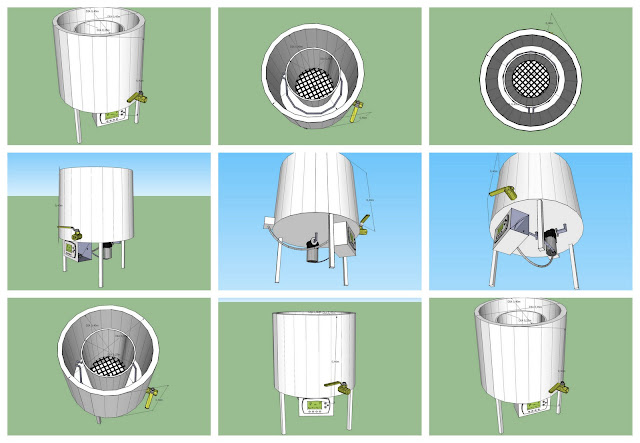

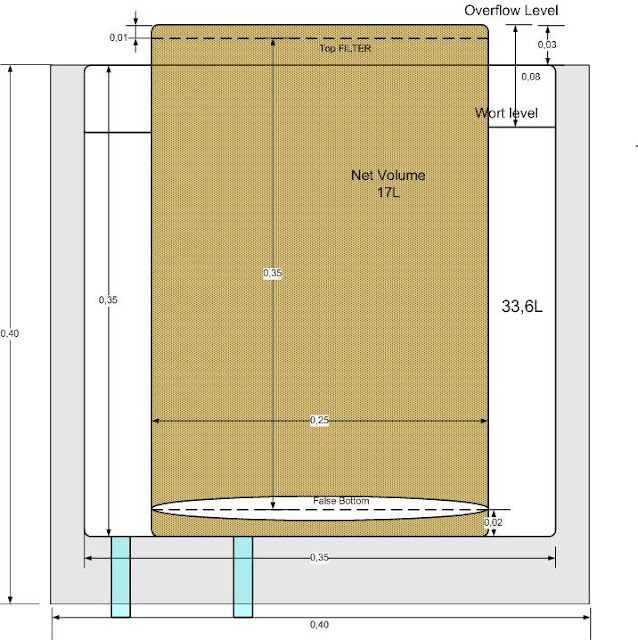

Here is some printout of Google sketchUP 3D CAD and a 2D drawings

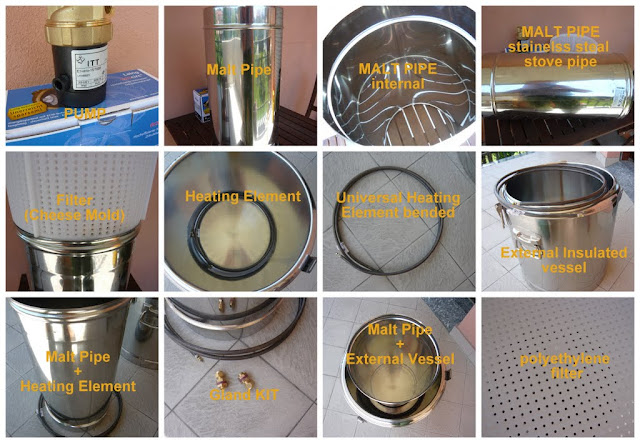

Inside the external vessel there is the “malt pipe” . I have used a light stainless steal stove pipe . The diameter is 25cm in order to have enough space for heating element, pump inlet/outlet and so on. Few centimeter from the bottom I have inserted a polyethylene false bottom cut form a cheese mold. The polyethylene is food grade and can resist to hot temperature, moreover it’s easier to cut and shape than stainless steal. The bottom of cheese mold has the right size hole and they are a little bit conical.

Considering empty space on the bottom and 1-2 CM of difference on the top the malt pipe I have a total volume of 18-19 L ( 25 cm radius x 40 cm height)

At the end there is the circulating pump…I think is a well known component for the recirculation…Laing Ecocric E1 with ½’’ inlet/outlet. It has been fixed on the bottom of the external vessel

enjoy

Davide

and what a great post

and what a great post