[center]

Filling and Priming[/center]

Filling

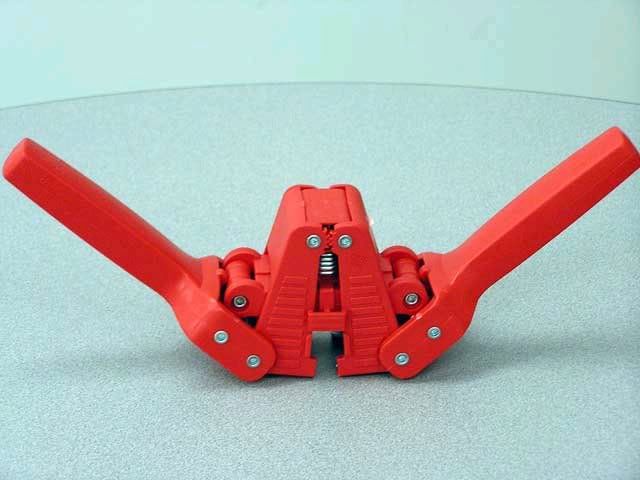

Probably the most useful and sanity-saving piece of kit during your bottling session will be a bottling stick or "cane". It goes right to the bottom of the bottle and when it touches the bottom, a spring loaded valve opens to release the beer for as long as the stick is pressed down. As soon as the stick is lifted off the bottom, the flow stops immediately. Bottling sticks are cheap, although the valves can eventually stick or get misaligned causing leakage. I seem to replace mine every six months or so but it beats having to manipulate a tap or syphon hose for every single bottle.

Priming

The beer in the fermenting or conditioning vessel is only lightly carbonated. To produce the characteristic “fizz” in beer, carbon dioxide ( CO2) needs to be introduced to the bottle. The most common method is to add a small amount of some type of sugar to each bottle, fill and cap the bottle and allow the small amount of remaining yeast in the beer to undergo a further fermentation over a week or more to produce the CO2. The other method, as used in most commercial breweries, is to pre-gas the beer in a keg or holding tank and fill the bottle with clear fizzy beer under “counter pressure” then cap immediately. Counter Pressure Bottle Fillers (CPBFs) are now available to home brewers but will be covered elsewhere on this Forum.

There are two main methods of priming bottles; Single Bottle Priming and Bulk Priming.

1. Single Bottle Priming

Using a small funnel and a teaspoon, the general rule of thumb is to add a rounded teaspoon of sugar to large (750ml or ‘quart’ bottles) and half a teaspoon of sugar to smaller (13 oz, ‘stubbies’ etc) bottles. This is quite vague and is difficult to adjust for different styles which required varying degrees of carbonation.

Some home brew supply companies sell carbonation drops which contain a measured dose of sugars. However they are hard to use with odd sized bottles such as pints or half litres.

2. Bulk Priming

Whilst slightly more work is involved, bulk priming is a method of providing a precise and uniform amount of fizz for each brew. The beer is racked into a separate sterilised container and dosed with a precise amount of sugar (dissolved into a syrup for easy blending).

It is extremely important to mix the sugars evenly with the bulk of the beer or uneven carbonation could result. I find the best method is to put the dissolved sugar syrup into the bottom of the second vessel and as the beer enters via the hose, as in the photo, it swirls around and mixes well, then a dozen stirs with a big sterile spoon(and with minimal splashing of course)should result in a perfect mix. The beer is then bottled out of this second container. This means that a range of bottle sizes can be used with each batch and will all be uniformly carbonated. How much sugar to weigh out and dissolve? Here’s a useful priming calculator which is quite self explanatory and easy to use in both metric and Imperial scales.

http://webspace.webring.com/people/ms/s" onclick="window.open(this.href);return false; ... lator.html

Of course you are not limited to white sugar when priming. Some brewers use dex, others use light dried malt extract and other fermentables. Bulk priming makes it easier to use a variety of priming sugars and the above priming calculator covers a few of them.

A Guide to Bottling.

A Guide to Bottling.